Container Ship Stowage Planning with Quay Crane Utilization

Principal Investigator(s)

Because of higher competition among ports in recent years, improving the efficiency has become an important issue in containership operations. One of the measures of performance is berthing time at port which is determined by the arrangement of containers both within the container terminal and on the containership. Most of the berthing time of a containership consists of unloading and loading time of containers. Determining an efficient configuration of containers that facilitates this process is an everyday problem solved by ship planners.

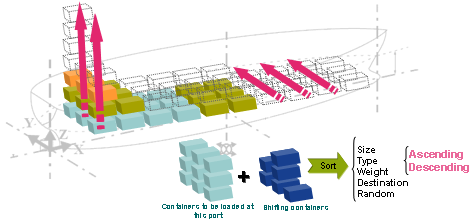

This research deals with the containership stowage planning problem which is the problem of stacking containers on different bays of a containership that visits several ports during a voyage. Containers may have difference types, sizes, weights and destinations. At each port quay cranes unload the import containers from and load the export containers onto the ship. Since the stacks are accessible only from the top, for unloading an individual container all the containers on top of it must be unloaded first. If the top containers have a different destination they must be loaded back onto the ship. Each of these extra movements is called a shift or re-handling which increases both the operational cost and ship turnaround time. In addition to that if the distribution of containers among the bays matches the configuration of available quay cranes at each port, the cranes can operate on the ship more efficiently. The stability of the containership must be retained during the voyage.

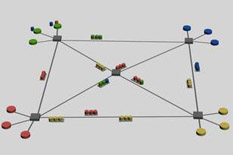

Intelligent transportation system (ITS) technologies offer the possibility to control the operations in real-time. Prior research efforts have considered real-time acceptance/rejection of shipping requests, but mostly have focused on truckload trucking operations. This study attempts to use real-time information in decision making for LTL carriers in the dynamic environment.

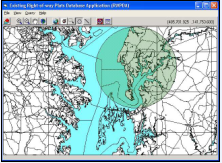

Intelligent transportation system (ITS) technologies offer the possibility to control the operations in real-time. Prior research efforts have considered real-time acceptance/rejection of shipping requests, but mostly have focused on truckload trucking operations. This study attempts to use real-time information in decision making for LTL carriers in the dynamic environment. The objective of this research project was to develop a prototype automated computerized system to perform queries on an existing right-of-way plat database. The system offers user-friendly interactive map-based interface. The system is specially designed to minimize organizational impact and eliminate the time-consuming manual query to the extent possible. All requests to the ORE related to plat database will be replied quickly as long as the query area is covered by plats that are in the database. In addition, the system is designed so that it can be further developed to serve network user, intranet-based users and internet-based user.

The objective of this research project was to develop a prototype automated computerized system to perform queries on an existing right-of-way plat database. The system offers user-friendly interactive map-based interface. The system is specially designed to minimize organizational impact and eliminate the time-consuming manual query to the extent possible. All requests to the ORE related to plat database will be replied quickly as long as the query area is covered by plats that are in the database. In addition, the system is designed so that it can be further developed to serve network user, intranet-based users and internet-based user. Evacuation Planning and Emergency Management is a sophisticated field of civil engineering sciences, aimed to save human lives by safe facility design and optimization of evacuation and rescue operations. Demand estimation, behavioral analysis, destination selection, and route selection are 4 steps of evacuation planning required before the actual plan set up and implementation. Recent approaches advertise integration of last 3 steps to achieve system optimal plans.

Evacuation Planning and Emergency Management is a sophisticated field of civil engineering sciences, aimed to save human lives by safe facility design and optimization of evacuation and rescue operations. Demand estimation, behavioral analysis, destination selection, and route selection are 4 steps of evacuation planning required before the actual plan set up and implementation. Recent approaches advertise integration of last 3 steps to achieve system optimal plans.